Super User

Aliquam erat volutpat. Proin euismod laoreet feugiat. In pharetra nulla ut ipsum sodales non tempus quam condimentum. Duis consequat sollicitudin sapien, sit amet ultricies est elementum ac. Aliquam erat volutpat. Phasellus in mollis augue.

Website URL: http://www.youjoomla.com

Referans 2

25 October, 2011Sed venenatis bibendum nisl, eget iaculis tortor imperdiet vel. In ut leo ut dui porta tincidunt. Aliquam erat volutpat. Vestibulum volutpat malesuada urna, in mollis tellus vehicula vitae. Fusce sed leo risus. Duis sagittis velit non lectus viverra cursus. Sed vel sagittis urna. Aliquam laoreet rutrum eros eu pretium.

Referans 1

25 October, 2011Sed venenatis bibendum nisl, eget iaculis tortor imperdiet vel. In ut leo ut dui porta tincidunt. Aliquam erat volutpat. Vestibulum volutpat malesuada urna, in mollis tellus vehicula vitae. Fusce sed leo risus. Duis sagittis velit non lectus viverra cursus. Sed vel sagittis urna. Aliquam laoreet rutrum eros eu pretium.

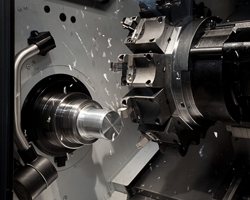

CNC MILLING AND EDM CRAFTING

24 October, 2011CNC (Computer Numerical Control), CNC means “computer counted management”. NC machine tools process otomatically with special standard holes drilled on the tapes. CNC machines are devices that process otomatically by being programmed with a mounted computer. Some of the examples; CNC Lathe CNC machining center CNC Milling CNC Wood processing machine Punch Machine press brakes CNC plasma machine. They are mostly used in the ship construction industry. It is used fot cutting horizontal metal plates (200 mm-3 mm). G (in preparation) codes, M (auxiliary) codes are used for using CNC machines. About he programming of CNC machines, there are two kinds of standard. 1-the ISO (International Organization for Standardization) Standard 2- DIN (German Standards Institute) standard. Machine manufacturing companies provided this codes more developed and more diverse systems within the framework of these standards. CAD (computer aided design) and CAM (computer aided manufacturing) programs are used so that CNC machines can be programmed more efficient, faster and error-free. Decided process stages for CNC machines on computer designs are controlled with simulation and G codes are developed. CAD, CAM, CNC: in the simplest terms, a machine that makes automatically a work requiring mechanical processing (punching, engraving, coloring, etc.) according to the commands from the computer CAD CAM CNC machines. With CAD, CAM, and CNC, if we bring the rectangular-shaped wood to circle shape by using hand tools, we draw a circle in a way that we want and cut the excess outside the circle with a saw. In order that it will be a beautiful circle, we work more rigorously on the circumference of circle with nail file and sandpaper and make our wood circle. If you have jig saw, you can make this work much more quickly. However, the full circle to be clean with sandpaper nail file again and you will need to work with sandpaper and nail file for the full circle.

PLASTIC INJECTION PRODUCT DESIGN

24 October, 2011At the first attempts in the plastics, Material properties obtained with test procedures applied for metals and design rules were used. Because there are very large differences between metals and plastics, this condition may lead to low quality though.

In addition to production ease, lightness and economic, aesthetic and being coloured properties are the biggest advantages. So the appropriate method selection and optimum desing method needs to happen in order that plastic materials perform the desired function in today’s highly competitive environment.

Today's plastics is a very important position in industry. Now plastics, for packaging of foods, are successfully used in almost every field up to transportation.

You must be careful at geometric design of the parts. You must follow the rules about scaling of parts like holes, ribs, teeth so that there would never be such problems as electrocution, spaces.

During design, Knowing about the basic information about chemical and physical properties of plastics will be also useful. Thus, the most available material helping that the part was successfully able to perform the desired function can be chosen.